I have been thinking a lot about shame recently.

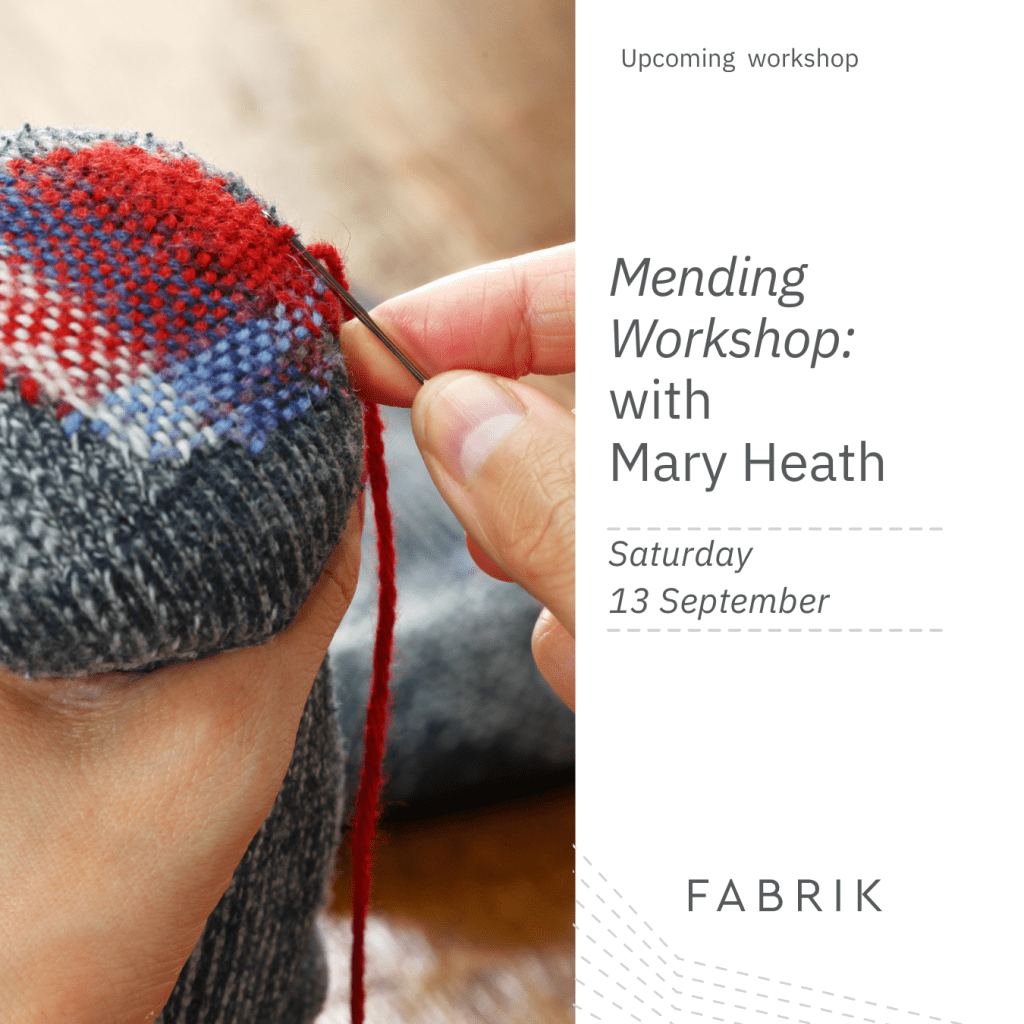

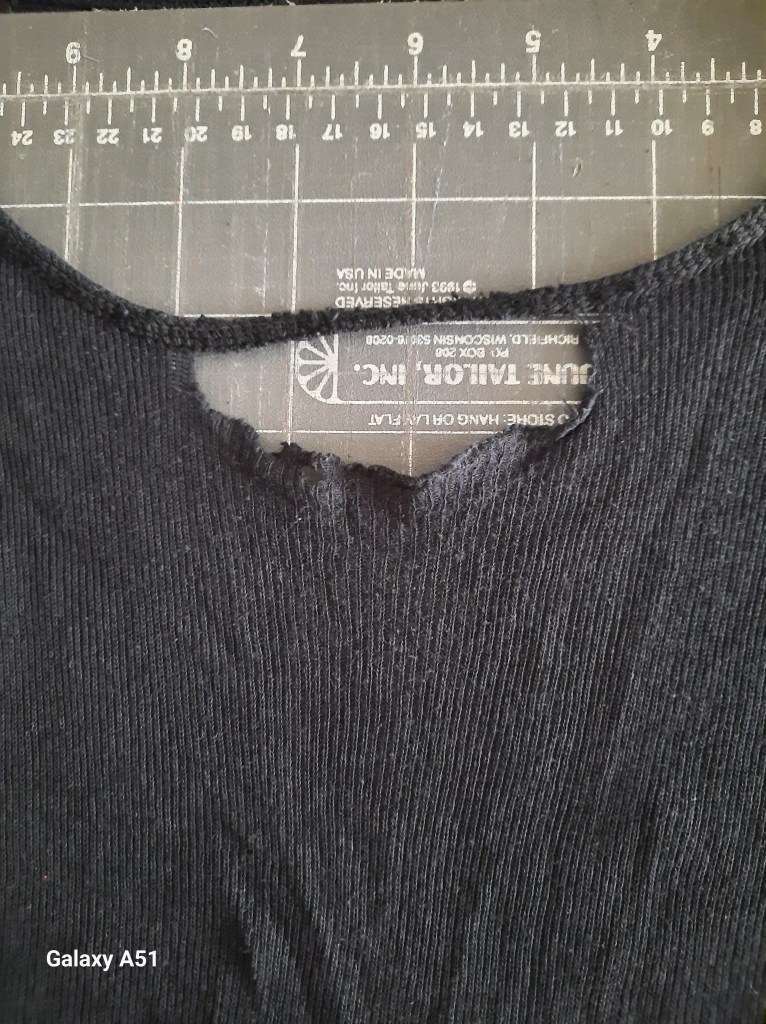

In my sewing, much of which now involves mending and making from often-threadbare discarded textiles, I think a lot about the associations between poverty and mending. I was taught to mend as invisibly as possible in order to extend the life of the garment being mended, while concealing the fact that it had required mending. The shame that many people feel about wearing mended clothing and using mended textiles seems to me to come from the thought that poverty is something people should feel ashamed of, and from the idea that bodies are shameful. Clothing that requires mending often bears the hallmarks of intense wear. It is the pattern of movement of the wearer that creates the level of abrasion that ultimately wears through the cloth.

When I first began to teach mending, people (usually women) bringing their clothes along to mend would often hesitate and apologise before bringing out their best loved jeans, worn through in the seat or between the thighs, to ask whether and how they could be mended.

Menders on social media have done some first-rate work in an effort to destigmatise mending necessitated by “chub rub” (usually used to refer to abrasion between the thighs) as well as making the “rear end mend” (mending the seat of a pair of jeans or other pants) a recognisable category of mending with its own hashtags, techniques and exemplars.

I did not realise when I began to teach mending, that I would need to speak about poverty and inequality so much. But some people who are mending from necessity, because they can’t afford more clothes, feel shame. People who can’t afford to buy high quality clothes in the first place, or who buy their clothes second hand, have more mending to do, sooner, than those who buy top quality and consequently expensive garments. Online mending accounts often show very much mended garments that were high quality to begin with, and therefore more likely to be perceived as “worth mending”, more likely able to be mended, and able to sustain a longer life as mends accumulate.

In this situation, who should feel shame? People who throw their clothes away (for whatever reason), or those who mend their clothes? Who should feel shame? Those who suffer poverty under conditions of profound inequality that are beyond their capacity to control as individuals? Or those who would visit the cruelty of shame on people who have less than they do, by blaming the individual living in poverty rather than the social context that makes poverty thinkable and an end to poverty unthinkable?

We are living in a climate and ecological emergency, where textiles are a significant global contributor to greenhouse gases and therefore the climate emergency. Textile production also contributes significantly to global pollution of air, water and land. Textile production and garment construction are highly exploited industries in which human rights and industrial rights are frequently abused across the globe. In this context, should people feel shame because they have clothes that require mending (usually because they have worn them a great deal) or should they feel shame if they are wearing their clothes very few times before disposing of them, like the average person in some studies of the subject in wealthy countries.

But one of the main reasons I have been thinking about shame is because I pick up litter. I pick it up around my home. I go out with my gardening gloves and pick up what I can as I warm up for a run, then put it in a public bin as I pass. I collect recyclables covered by container deposit legislation in my state, for which a ten cent deposit can be claimed. When I have a big pile of them, I take them to my neighbour’s place and he donates the proceeds to Food Bank—which supplies food to people who need it. A service which should not need to exist, but does need to exist. When I want a walk around my neighbourhood, I take a bucket with me and my garden gloves, and I pick litter as I walk my neighbourhood. Sometimes people look away or even cross the road, because apparently I am doing something shameful. Sometimes people tell me I am doing the Council’s work for them. As if caring for our neighbourhood has been outsourced to the local council and no one else can, or should, participate. Sometimes they thank me. It does seem that the difference turns on how I am dressed at times. Am I in my gardening clothes (and perhaps muddy with it)? I am more likely to encounter reactions that treat me as shameful—perhaps this is about an assessment of my class location or my assumed poverty. If I am well dressed I am more likely to be congratulated. But it does also turn on the other person, and perhaps how warm and friendly I am behaving on that particular day.

I think I am litter picking more, as the state of the world bothers me more. As genocide continues unabated in Gaza without effective international intervention, war in Ukraine continues, and wars rise in other parts of the globe. As the climate crisis deepens. As signs of fascism rise. I do what I am able to work out to address these things. But they cause me such profound concern and distress, and they are so far beyond my personal control that doing something for earth care and people care that has visible results is in some way a comfort. This may be over analysing the situation! I also like reducing the amount of waste blowing through my neighbourhood, the amount of glass being smashed, and the amount of littler entering Willa Willa, the local creek—or going out to sea through the storm water system. I like being a community carer. I like getting exercise. I appreciate knowing the neighbourhood in detail and understanding more of what goes on in it.

But the time I thought most about this question of shame, was while carrying out three days of community service after my most recent civil disobedience. I was arrested for interrupting a speech by the Minister of Mining and Energy, at a Roundtable on Oil and Gas, together with several fine people. After a lengthy time on bail, I was sentenced to three days of community service and assigned to a litter collection crew. I had to go to the depot in my area, sign on, collect my high vis vest, and get into a bus with others on community service, together with our supervisor. The van said Repay SA, just to make sure that everyone knew that people on community service were inside. The supervisor reported being called by his supervisor, when that van was parked near businesses, services or people who objected to the presence of criminals in their vicinity, and asked to immediately move it.

So there I was, picking up litter for three days with the rest of the crew. I thought a lot about the Magistrate who sentenced me. He was very clear that he needed to communicate to me (and my co-accused) that the community denounced our crimes, and that we should feel ashamed of ourselves. I thought about this long and hard and could not find it in myself to feel ashamed. I do not feel ashamed of my friends and comrades, either. In all honesty, I feel proud of us all for being prepared to take this action. It was not the first thing we chose to do, to draw attention to the climate crisis and try to motivate people (but especially politicians and industry) to take action commensurate with the scale and speed of the emergency we all face. We all had done many law-abiding, quiet things as well as some law-abiding and less quiet things, by this point. But living in a society where our political leadership and the media behave as though they have never encountered climate science and we can all carry on our lives as usual? Makes me feel as though I am living in a parallel universe. I feel a moral and political imperative to take action on the reality I believe we face—having formed that belief on the basis of internationally recognised, peer reviewed science. I don’t feel ashamed of acting on that imperative. I wish that circumstances were different. But they are not, and that is why I went to the Roundtable prepared to be arrested and sentenced.

My friends laughed when I said I had been sentenced to community service. They think that my life has been committed to community service. Some of them think my climate activism is community service. They also found it hilarious that I had been sentenced to do something that I do willingly and often—collecting rubbish.

I thought a lot about that, too. In our high vis Repay SA vests and with our Repay SA van, members of the public mostly did not engage with us and gave us a wide berth if we encountered them. We cleaned up along road sides, in parks, and in places where homeless people had been living or in places in the parklands where people go to do things out of sight. That is not my life, such is my luck. I don’t think it should be anyone’s life. I feel shame that we live in a society where some people don’t have homes, and some live without access to running water or a toilet. Where people take illicit drugs out in public space, in filthy circumstances, hidden away where help is unlikely to come if something goes wrong. Those things shame me.

Cleaning up public spaces? That does not shame me. I think it is walking by and doing nothing when a flock of wet wipes has been released in my neighbourhood that is shameful. Not picking them up. I think it is eating your takeaway meal, smoking your cigarettes, drinking your beverage of choice and then leaving all the litter that creates in the car park that is shameful, not me picking it up. But then, living in a society where takeaway food and drink is such a thing, and people’s life circumstances are such that there is so much eating and drinking and drugging going on by the side of roads, in car parks? That speaks to me of misery. It speaks to me of our collective failure to treasure the natural world, finite resources, and human connection, that we have this phenomenon and we do not have people eating together, in places much more pleasant and social than a car park, instead.

I am doing what I can think of, to address this. It is not a one person sized problem. But mostly, I am picking up litter and thinking about why it is there, what it means, what might change that. I am not feeling ashamed of myself.

Spending three entire days collecting rubbish confirmed for me that we have some serious problems to address. Each day we went to a different rubbish dump or waste transfer station. That was educational and it was not reassuring. On my third day on the crew, we went to a council area where there is no hard waste collection. In my city, it is common for local councils, who have responsibility for rubbish collection and recycling, to offer a service where they will collect large items that residents want to dispose of. Some councils have a nominated day a few times a year, some require residents to book a collection for a limited number of times. In either case, people put their unwanted items out on the kerb or footpath for collection. Sometimes other people collect them before the council can. It is common to see broken furniture and old mattresses, pieces of carpet and broken toys or appliances. Our crew went to a council area where there is no such collection and instead, the Repay SA crew go out almost every week and pick up what is lying around that council area. Doors, bedding, sports equipment, kitchen supplies, pots, packaging in large quantities, discarded items from building sites. You name it.

I don’t feel ashamed of collecting this stuff! I did feel ashamed to see it would all just go to landfill. That no effort was made to put it to reuse or save what was valuable or even recyclable (we had buckets to put container deposit cans and bottles into, but that was the limit). I feel ashamed of that council for choosing this as the way it would manage or fail to manage its residents hard rubbish. But our efforts to clean up stuff left all over their suburbs? I’m not ashamed of that.

Yours sincerely, unashamed of taking climate action and unashamed for doing what I can to clean up for social failure and to mend all that can be mended.