When these walnut hulls came home from the Guild hall with me, who knows how long they had been stored? I can only give an educated guess to the time involved in separating them from the walnuts… or the year in which that might have happened. In the meantime, insects had become involved… so I put them in water and put a lid on and left them to steep in mid to late May 2014. As you may remember, I decided I should honour the effort involved in all that dye gathering and storage… and so over a month later, a dye vat emerged…

The stinkiness of which was unholy. It may become a legend in my Guild. But not in a good way! The dye that emerged was inky and impressive. I rather wish I had saved some to try using it as ink, but in all honesty I didn’t have that thought on the day… my nostrils said ‘begone!’. The dark brown skeins in the foreground are walnut.

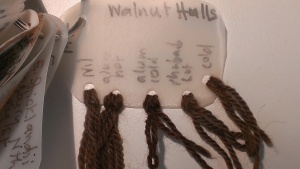

And here is my sample card.

Interestingly, the walnut dyes, together with every dye I have tried on both hot and cold processed mordants so far, show cold processed alum as the most obviously effective mordant, with hot processed alum coming second. The cold processed sample is noticeably darker than all other samples. My eye cannot detect a difference between the hot and cold processed rhubarb leaf mordant samples. In this case, I expected that since I used an overwhelming quantity of rhubarb leaf, achieving a dye effect and not just a mordanting… that these samples would be a stronger shade of brown. I can’t detect a difference between the rhubarb leaf mordanted samples and the no mordant sample. So far, I have to concur (sadly) with Pia at Colour Cottage in finding that rhubarb leaf is not terribly effective as a mordant, at least in the ways I have applied and used it. I have enough mordanted yarn to continue experimenting for some time to come…

Such a nice rich chocolate brown! I’ve never gotten such deep results… perhaps I didn’t have enough walnuts!? Now I have to go on a walnut quest!

LikeLike

It’s true we had a very good ratio of walnuts to weight of fibre… but one of the reasons I was prepared to long soak (AKA ferment) my walnut hulls was that I have heard other dyers report that this gives better colour. The dye bath was very deep brown even before I put the heat under it. But now you’ve been warned–about the smell!

LikeLike

Smell? Could it smell any worse than a fermenting pot of urine being saved for indigo dyeing? 😉

I didn’t try fermenting the walnuts before…. I will this time! But it will be done outside!!

LikeLike

Not everyone has the nerve or the stomach required for every kind of dyeing adventure 🙂 Outside is the place for a lot of life’s big adventures, I reckon!

LikeLike

True….. unless you live close to neighbors with sensitive noses!

LikeLike

I am currently enjoying a dyeing workshop with Michel Garcia in Scotland. today we used walnut hulls with gall nuts and citric acid to make a brown colour .. and rhubarb root for a yellow dye with the same – also premordanted some fabric with rhubarb and then dyed with madder. all very fascinating and great colours, but the plant materials are all prepared already, in plastic bags, provided by Michel.

LikeLike

Lucky you! Sounds wonderful!

LikeLike

well, that answers something I’ve been wondering about with all this fermenting of plant stuffs, etc….since I’ve so far just been a vicarious dyer. Although the leftovers from a pot of hibiscus tea the other day did make a nice pink pattern on some folded sumi paper.

LikeLike

🙂 it isn’t all stinky! Eucalyptus and madder smell rather good, I think.

LikeLike

Pingback: Walnut, weld and purple fountain grass | Local & Bespoke