I began the final stage of preparation for my natural dyeing workshop by packing the car to capacity the night before and steeping logwood and madder in hot water. These are more of the dyes that have been left at the Guild. It seemed good to share them with other Guildies this way.

I came through the parklands on my way to the Guild and stopped in homage to a few trees. This one turned out to be E Tricarpa…

The unpacking was quite a thing. This is a view of the back seat of the car before unpacking.

The steeped fermenting walnut hulls (another dyestuff left at the Guild) travelled in the front seat footwell, in a pot with a lid, in a big bucket in case of spills. No spills. Whew!! I put heat under them an hour before people arrived in hopes of getting it over with. My friends, I will never do this again. It may take me years to live down the smell this dye pot gave off! At one point when a heater went on, someone told me they had found a dead mouse in the heater. When I went to see, they were looking for a mouse they were sure must be in there because they could smell it. Cough! The women who were rostered on in the Little Glory Gallery in another part of the Guilds premises exclaimed. So did the treasurer, who came in to work on the books and was similarly appalled. Eventually walnut tailed off and a eucalyptus bark dyepot began to prevail. The smell of natural dyeing had people who had come to the gallery wanting to come and see what we were doing all day! I give you the walnut hulls I will be living down at the Guild for years to come. They produced an inky dye. Truly impressive.

I set up a bit of a display table of yarns and knits, leaf prints, tea cosies, sample cards and books.

People had their first go at India Flint’s eco-print technique. Some had read the book but never tried it. I don’t know how people can resist! The Guild has a copper which had been repaired because we were planning to use it. Use it we did!

My Mum deadheaded her African marigolds for me through summer and they made a great yellow.

I tried grinding the soaked madder in a blender as Rebecca Burgess suggests (the second hand blender was pretty challenged) and here it is in the dye bath, in its own stocking… we got some lovely reds.

I used one of the bottles of pre-ground cochineal that had appeared in the dye room cupboard. The colour was entirely startling!

There was a pot of logwood that came out so deep it was virtually black. There was a pot of E Scoparia bark that gave some burgundy on the first round and some tan for a skein added in later. There was an E Scoparia leaf pot and an E Cinerea leaf pot–oranges of different shades. The dye room at the Guild has four gas burners as well as the copper–so we went wild.

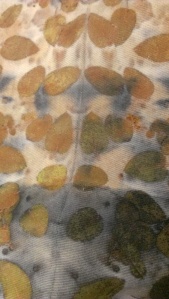

The wonder of unwrapping eco print bundles never wears thin!

I used the opportunity of being at Beautiful Silks in March to acquire organic wool as well as silk noil twill and some silky merino for this workshop. E Cinerea did its wonderful thing.

And so did human imagination…

The string print on the upper right of this next image was a lovely surprise…

It was overcast and the results of the dye vats which were the focus of the day are seen here in all their glory drying in the Guild car park! These are eucalyptus and logwood.

These are cochineal, madder and marigold. I had mordanted some silk paj in alum and taken it along. I tried eco printing it years ago and didn’t think much of the results. Wendi of the Treasure suggested jewellery quality string (which sounds very promising to me), so I’d been planning to eucalypt dye them–but took this opportunity to expand my palette. The silk went orange in the madder bath even though wool in the same bath was much more red–still good.

People made their own series of test cards too.

It was a day of happy experimentation, I think, the smell of fermented walnut hulls fighting it out with stewed eucalyptus bark notwithstanding. The people who came were friendly, warm and generous–a delight to be among. It was a treat to be in the company of other people who are fascinated by eucalypts and by the dye possibilities of plants. Folk were talking about what they might do with their cloth and how they might approach their neighbourhoods differently… I hope that for at least some it will be the start of an exciting new journey. By the end of the dye I was deeply weary. I took the logwood, madder and cochineal baths home with me (after taking suitable precautions against spillage) and began some exhaust dye baths next day. But by late afternoon I was down to twining silk string mindlessly and happily…