The woad has been thriving in this time of rain followed by warmth. (The potatoes aren’t doing badly either, as you can see). And that can only mean one thing, when free time opens up!

I managed to obtain Jill Goodman’s A Dyer’s Manual recently, and had the benefit of others helping me to grasp the chemistry of fresh woad and how it differs from using indigo that has already been prepared from fresh plants by someone else. I came by the book at the annual spinner’s retreat where there were folk with interest and knowledge–perfect, and very helpful indeed. So this time I felt I knew why I was adding air in the early stages of the process, only to then remove it in the de-oygenation process required to have the dye become fully soluble and able to attach to fibres. Previously this has been a total mystery or had me feeling I had done something wrong, or both.

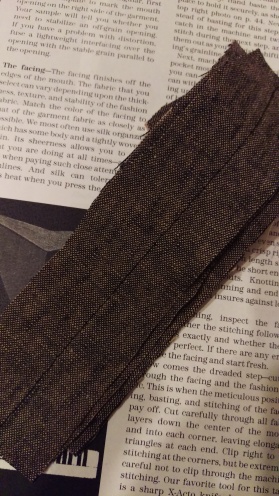

I still had part of one package of hydrosulphite left. I am pretty keen to have it be the last. Hydrosulphite is a substance the earth could do without. But equally, since I have it, better to use it rather than let it become stale and unusable for this process. So I tried two vats: one with hydrosulphite and one with fructose. The picture above is grey merino fleece descending through the ‘flower’ on the surface of the hydrosulphite vat and into the yellowy depths below.

This image is the fructose vat, which involved some guesswork on my part (no way to measure how much woad pigment there was in my solution). I am not experienced enough to have great judgment or to trust my own judgement. I can measure temperature and I can measure Ph. The complex part is judging the reduction (de-oxygenation) of the vat. This looked very promising to me! That said, there were moments when I had realisations that gave me pause. Jill Goodman, for example, seems to live in England and I suspect her conditions and mine are not the same. She goes from scalding leaves with boiling water through various processes to heating the vat to raise it to 50C (there was a lot of conversion to metric involved for me)… I did the processes concerned and still had a vat at 70C and decided in the end to put the vat in a sink of cold water and ice!

This linen scarf did the amazing woad magic of going from yellow to green to blue when put out into the air.

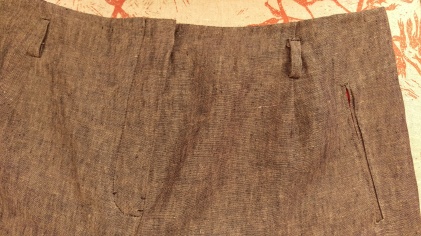

Both of my tied textiles dyed only on the outside and therefore were re-tied and re-dipped. The greeny-blue of the image above converted to blue very quickly on rinsing (you can see an image further down).

Soon I had dyed my planned fabrics and imagined that the vat would be exhausted, because previous vats have yielded so little. The next day it was clear that the hydros vat was not exhausted, so I adjusted Ph and temperature and set about continuing to dye. The fructose vat was still not reduced, so far as I could tell with a test dip, though again it looked promising and eventually looked much like the hydros vat. However, it still had not reduced, and thus, was unable to dye. In the late afternoon I decided it probably didn’t have any dye in it. Do not read on if you have a weak constitution–but one of the reasons for my belief was that I had accidentally boiled the fructose vat early in the process. Eeek! I had a very little hydros left, so added some to the fructose vat. Then half an hour later, a little more. 30 minutes later, it came into order and began to dye, and I dyed using both vats until bed time using the only clean fleece I seem to have. The fructose-hydros vat dyed over two more days, as it turned out!

I threw in more cloth and went to bed, feeling extremely pleased. On the down side, I used hydros. On the up side, it can only have been a matter of time before that fructose vat would have reduced. I just needed to hold my nerve and be patient. Maybe add more fructose. Admittedly, time is one of my biggest issues because I do have a day job and other commitments. However, this is by far the most successful woad effort to date. I now understand that I need to use a vat rather than direct dyeing for the woad to be wash-fast. I think I now have a sense of how to tell whether there is dye in the vat (at all) as I process the solution. The low concentrations of colour claimed for woad are not so low as to make it useless, and I have quite a bit of leaf. One vat with 1.6 kg leaves and one with 900g leaves from one part of the garden where other things have struggled to grow well–and this is my second harvest from them. I also have the happy sense that my understanding is sufficient to reach success with a fermentation/fructose vat given time. The pigment from my previous crop of woad is in a different vat which has not shown promise even though I have been waiting for weeks. But it still may! And I am confident now that reduction is the main issue and not one of the other possibilities. Very encouraging mellow blues–and more pictures to come when everything is clean and dry.